first firing

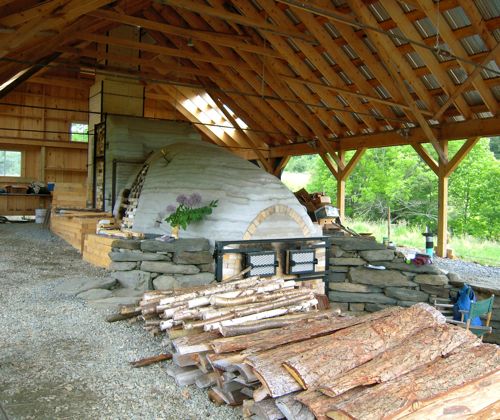

Two years, eleven months, and sixteen days after breaking ground on our two-chamber climbing kiln, we lit the first fire. Stacked with over 700 pieces of mostly raw and unfired pottery on 121 kiln shelves, we were ready to see how our creation actually worked!

The first couple of days of the firing were fairly quiet. We burned hemlock and a hard wood mix fairly slowly, starting in the four-foot long opening at the bottom of the kiln, and gaining just 25 degrees per hour, or 150 degrees per shift. Nathan and I split up the days by taking six hours on and six hours off, so one of us was always at the kiln, taking good notes and taking it all in. (The other was trying to get a bit of sleep! 12-6, 6-12, 12-6, 6-12, you get the idea.)

The kiln was really responsive and fairly easy to control at this stage . . . we were learning each other, and enjoying ourselves. Friends brought dinner, and good company, even homegrown strawberries and fresh milk for coffee. (Thank you Becky, Chelsea, Dave, Sarah, Bob, and Sarah!)

We were really pleased with our firebox design, which is a sort of stepped down staircase filled with air channels for efficient burn. The four-foot lengths are stoked first through the opening in the bottom of the kiln, and eventually through the doors on top, alternating, and stoking wood every 5-10 minutes. The slab of wood sits on the 'stairs' and burns all along its length. Below is a photo of the inside of the firebox taken before we loaded the kiln.

We burned a lot of wood. One of the biggest learning experiences during the firing was that our chimney is SUPER powered. (As in, a very big opening.) It drew a lot of the heat across the bottom of the kiln and out the stack, causing us to consume more wood than we hope to in the future. (We'll close up the flues a bit more with bricks, so it doesn't pull quite as hard!) We estimate that we burned about 5 cord of scrap hemlock and pine slabs, and 1 cord of hardwoods. Thank goodness for our wonderful friends who stopped by nearly every day to help us move wood up to the kiln front for us; we were so glad we had TONS of wood on hand and at the ready. (Thank you Grace, Matt, Chelsea, Dave, and Charlotte!)

Side stoking (putting wood into the sides of the chambers in addition to, and then instead of the front) began in earnest in the wee hours of the fourth day. At that point, the pyrometer (basically a high-temp thermometer) we had salvaged had ceased to give us a reading (it only went to 1,999!) so we were firing solely using cones and blowholes (pictured above) as indicators of heat and internal atmosphere.

By hour 90 or so (the morning of the fourth day), we had reached cone 12 in the front of the kiln, and needed to stop stoking there, and move onto solely the side stoking ports in the back of the first chamber, and in the soda chamber. The narrow gauge dry wood ignited on contact.

Thankfully, we had great help at this point. Our friends Kaitlyn, Sarah, and Matt (all potters!) showed up with food and most importantly, fresh energy. At this stage, we were both running on very little sleep, but nonetheless feeling energized and excited by all that was going on. (Thank you, adrenaline.) If the rest of the firing were a slow jog, these last few hours were a flat-out sprint. We moved quickly to get the soda chamber infused with soda (soda ash mixed with some whiting and borax, made into a paste, and stoked into the kiln on boards), and to raise the temperature evenly throughout.

We checked cones and pulled draw rings, and were pretty happy with what we saw. We would have liked it hotter in some places, and cooler in others, but that's wood-firing! (Especially the FIRST wood-firing.) By eleven-fifteen that morning, after 94 hours of firing, we were ready to shut it down. All the plugs went back in, the damper was closed, and we did a wee bit of collapsing celebrating. It's safe to say that regardless of the results, this first firing was a huge success in many ways. We are grateful for the experience . . . and hoping and waiting for at least a few (?!?) nice pots.

We did it!

P.S. Cooling takes an entire week. Stay tuned. We can hardly wait.